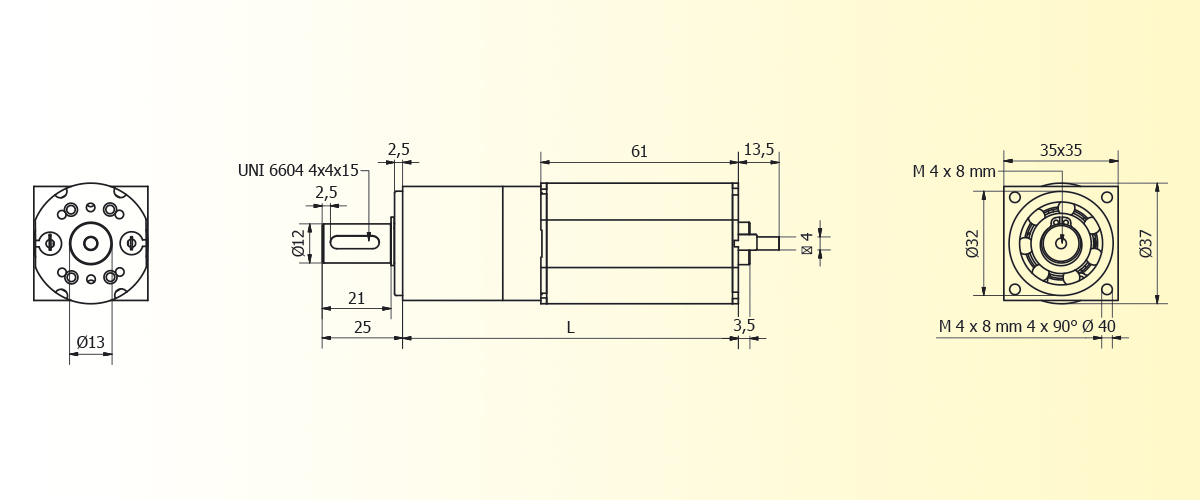

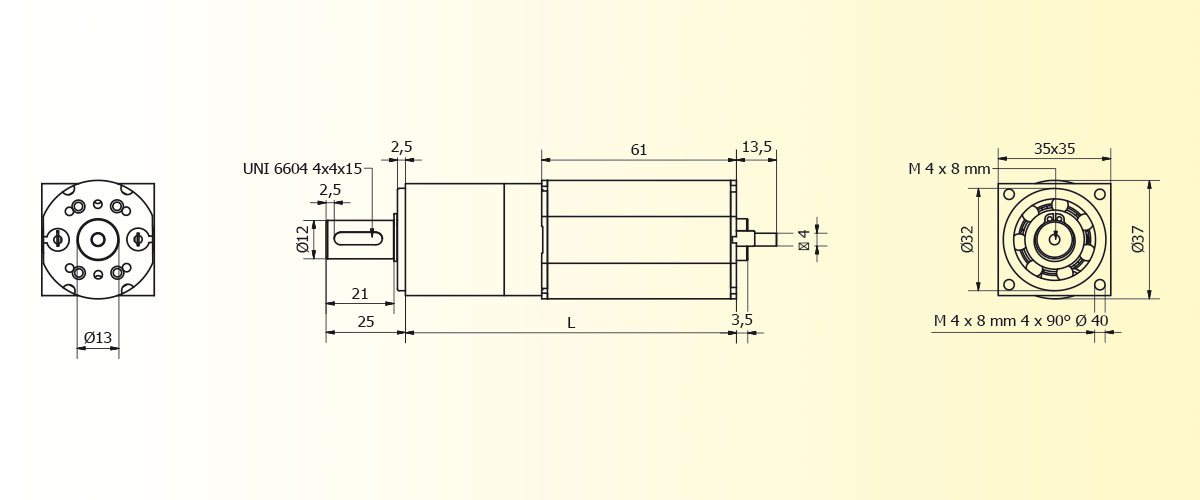

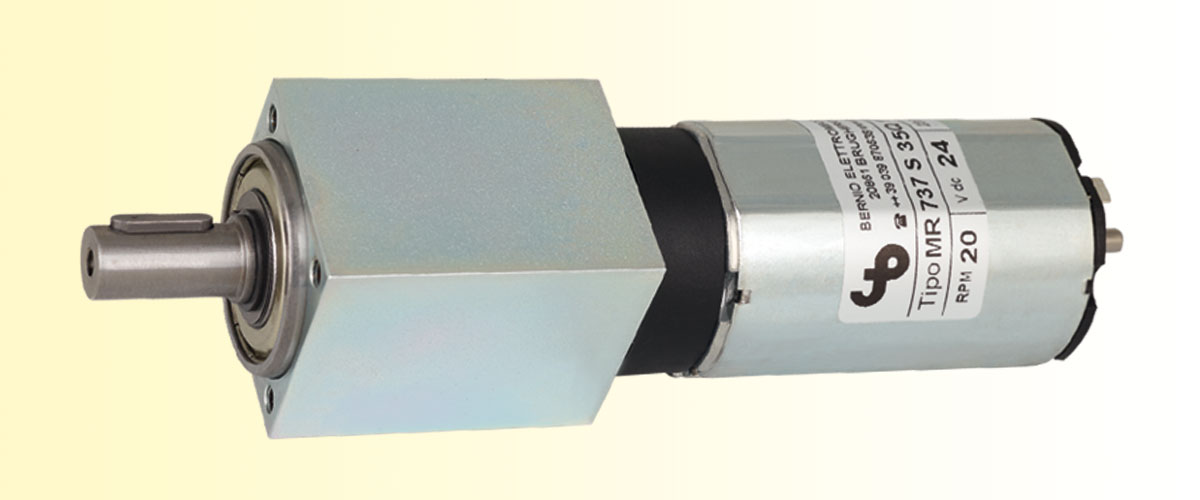

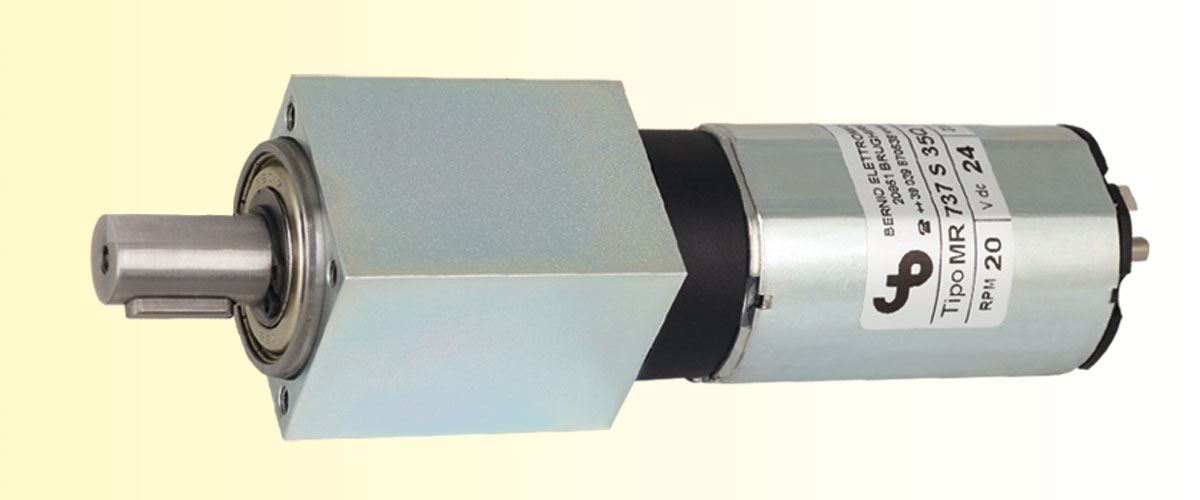

GEAR MOTOR MR 737 35Q

|

|

|

TYPE |

Ratio | L mm |

Efficiency % |

R.P.M. No load |

Ampere I S1 |

R.P.M. S 1 *min-1 |

Torque S1 Nm |

Ampere I S2 |

R.P.M. S2 *min-1 |

Torque S2 Nm |

Ampere I Max |

Nmax torque Nm |

| MR 737 H 35Q | 16 | 104 | 82 | 440 | 1 | 408 | 0,25 | 2 | 360 | 0,65 | 10 | 3,5 |

| MR 737 S 35Q | 16 | 104 | 82 | 310 | 1 | 265 | 0,43 | 1,7 | 120 | 0,85 | 5,5 | 3 |

| MR 737 L 35Q | 16 | 104 | 82 | 165 | 0,35 | 140 | 0,22 | 0,55 | 118 | 0,43 | 1,6 | 1,5 |

| MR 737 H 35Q | 64 | 113 | 73 | 110 | 1 | 102 | 0,86 | 2 | 90 | 2,1 | 10 | 12 |

| MR 737 S 35Q | 64 | 113 | 73 | 80 | 1 | 68 | 1,43 | 1,7 | 57 | 2,8 | 5,5 | 10 |

| MR 737 L 35Q | 64 | 113 | 73 | 40 | 0,35 | 35 | 0,7 | 0,55 | 28 | 1,43 | 1,6 | 5 |

| MR 737 H 35Q | 256 | 121 | 65 | 28 | 1 | 26 | 3 | 2 | 23 | 7,5 | 3,5 | 15 |

| MR 737 H 35Q L | 256 | 130 | 65 | 28 | 1 | 26 | 3 | 2,5 | 21 | 10 | 4,2 | 28 |

| MR 737 S 35Q | 256 | 121 | 65 | 20 | 1 | 17 | 5 | 1,7 | 14 | 10 | 2,4 | 15 |

| MR 737 S 35Q L | 256 | 130 | 65 | 20 | 1 | 17 | 5 | 2 | 13 | 12 | 4,5 | 28 |

| MR 737 L 35Q | 256 | 121 | 65 | 10 | 0,35 | 8 | 3 | 0,55 | 7 | 5,5 | 1,2 | 15 |

| MR 737 L 35Q L | 256 | 130 | 65 | 10 | 0,5 | 7,5 | 5 | 0,9 | 5 | 10 | 1,6 | 20 |

| MR 737 S 35Q | 1024 | 130 | 57 | 5 | 0,4 | 4,8 | 4,5 | 0,6 | 4,6 | 8,5 | 0,7 | 15 |

| MR 737 S 35Q | 1024 | 130 | 57 | 2,5 | 0,23 | 2,3 | 4,5 | 0,33 | 2,1 | 9,3 | 0,44 | 15 |

Lenght of the gearmotor as a function of reduction and the number of output turns. Motors 737 have powers 10 - 20 - 25 W, voltage 12 or 24 VDC (version 737 H only 24 VDC).

This data sheet refers to the 24 VDC version.

Output shaft is supported by two screened bearings. The motor’s surface and reducer’s surface are both zinc plated to avoid corrosion. Permanent greasing.

The motor has an electrical suppressor system for the CE standard. The speed rotation can change of +/- 10%.

Max load act on the extremity of output shaft: Axial 300 N - Radial 400 N

The S1 continuous load test was made in the air with an increase of temperature of 70° C.

The S2 intermittent (50% timing: 5'ON – 5'OFF) load test was made in the air an increase of temperature of 80° C.

The starting current (I max) must not maintained for more than 2” (seconds).

It is possible to apply an our Encoder.